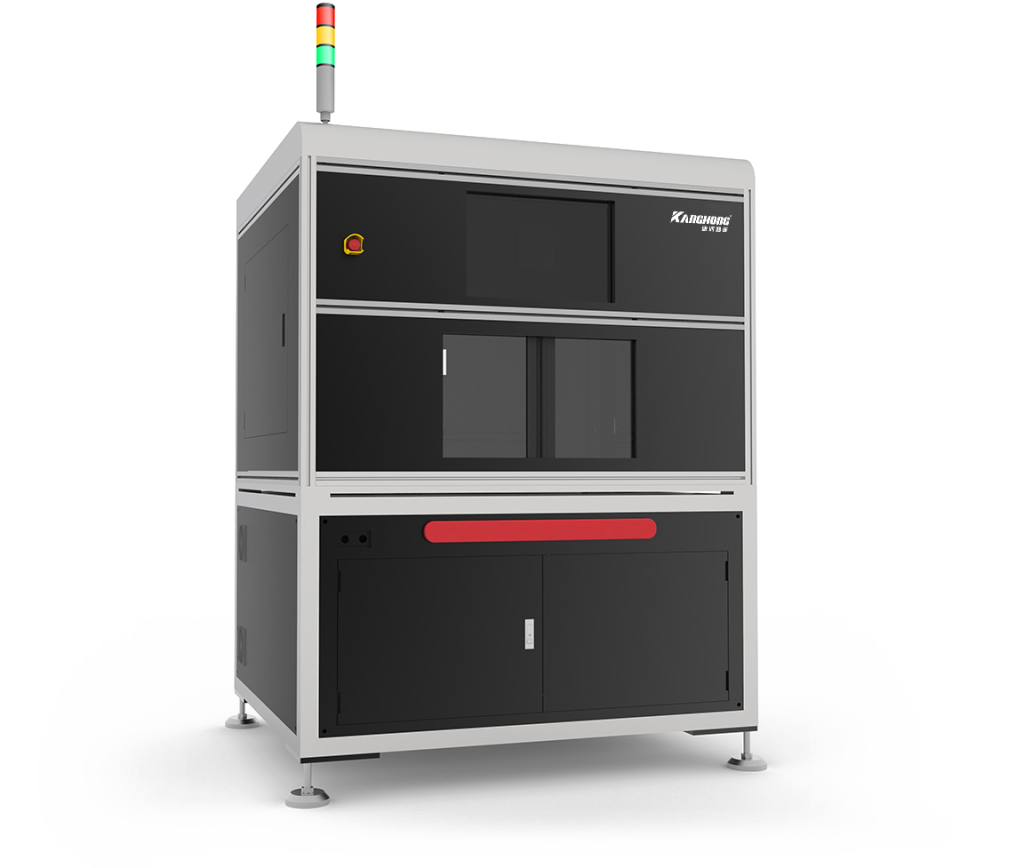

Kanghong Intelligence is a detection and repair equipment for consumer electronic products, mainly oriented to the size detection and plastic repair of thin metal deformation, such as laptop computer, tablet and mobile phone metal shell.

Size detection using high precision and high performance measurement sensor, can be used for object size measurement, such as parts height, edge, diameter, wire diameter, width, clearance, inside diameter, outside diameter and so on. The height of the product is measured by the sensor, and then the deformation of the product is calculated by the software and output to the software interface.

Plastic repair is based on the mechanical properties of metal materials, apply external force to the product, so that the product in the molding deformation stage of the shape change. The deformation size of the product is measured by the sensor. After AI calculation, different forces are applied to different deformation sizes to change the deformation amount of the product and repair the deformation amount of the product to the size range required by the customer.

We are very much looking forward to meeting you and learning your needs!

Difficulties in quality control

Advantages of Equipment

Consult more